Alumina ZirconiaDZA

Description:

DZA is an eutectic mixture of aluminum oxide and zirconium oxide obtained by melting both materials in an electric furnace.

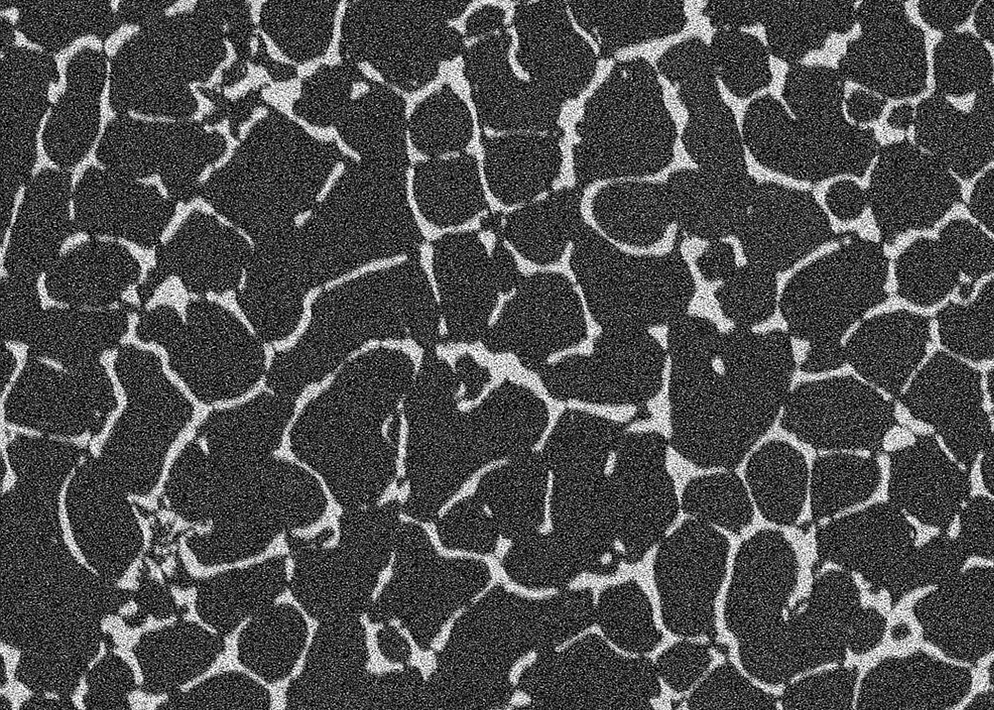

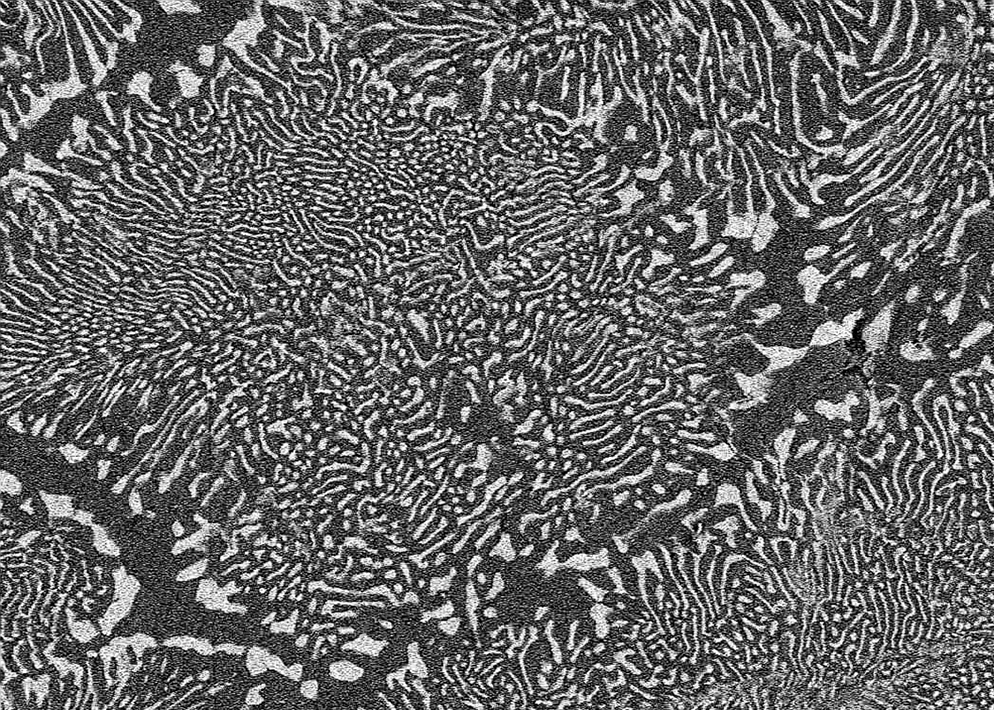

The controlled melting process and the special cooling procedure of crystallization solidification make it possible to obtain a microcrystalline texture with an alumina-zirconia eutectic crystalline structure and low porosity.

DZA-40 is for coated abrasives and is has extremely fine crystalline microstructure.This structure allows an excellent cut rate at low pressures, outperforming.

DZA-25 is for bonded abrasives and it has fine crystalline microstructure with alumina-zirconia eutectic crystalline structure. The most common applications are for high pressure grinding wheel and for blasting on very hard surface.

Physical Properties:

| Property | DZA-40 | DZA-25 | |

|---|---|---|---|

|

Chemical Composition (wt. %) |

Al2O3 | 59.0 | 75.0 |

| ZrO2 | 39.4 | 23.7 | |

| SiO2 | 0.35 | 0.35 | |

| Fe2O3 | 0.15 | 0.15 | |

| Y2O3 | 0.85 | 0.05 | |

| Na2O | 0.12 | 0.15 | |

| CaO | 0.09 | 0.09 | |

| TiO2 | 0.15 | 0.50 | |

|

Physical Property |

Specific Gravity (g/㎤) | 4.60 | 4.25 |

| Vickers Hardness (㎬) | 19.0 | 21.0 | |

Microstructure: