Production Process

DAEHAN CERAMICS is continuing efforts to maintain a higher quality and investigating the development of new ceramics materials.

Sintered Alumina

1Shaping

Mix alumina and binder and make the diamond like shape.

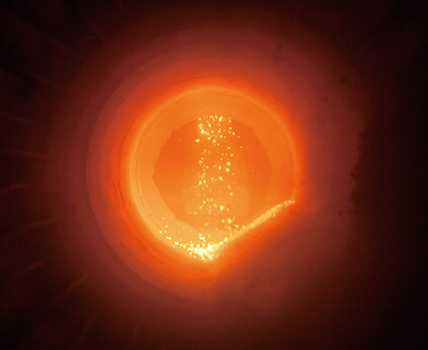

2Sintering

Sinter the diamond shape pellets over 1,800℃ in rotary kiln.

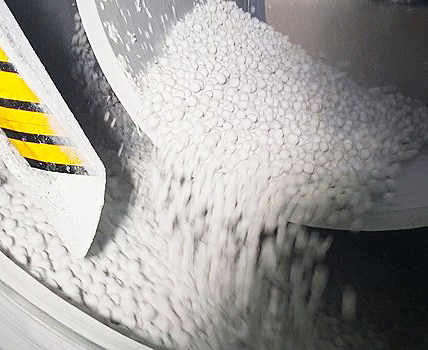

3Crushing

Crush the sintered pellet by size.

4Inspection & Packing

Inspect the product quality and pack it in the bag.

Sintered Spinel

1Grinding

Grind the raw material.

2Mixing

Mix the ground raw material at a certain ratio.

3Shaping

Make a shape of mixed slurry.

4Sintering

Sinter the dried pellets over 1,850℃ in rotary kiln.

Tabular Alumina

1Shaping

Mix ground alumina and water to make shape.

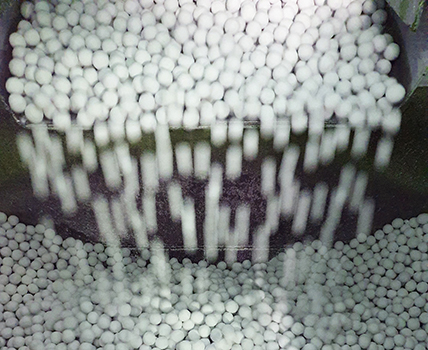

2Drying

Dry the ball like shape pellets.

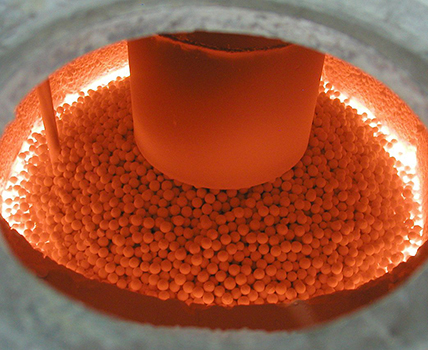

3Sintering

The dried pellets are sintered over 1,900℃ in shaft kiln.

4Crushing/Packing

Crush the sintered pellets by size and pack in the bag.

Fused Alumina

1Melting

High purity calcined alumina is continuously melted in an electric arc furnace.

2Cooling

The melt is poured into a pot for cooling and recrystallization.

3Crushing

The ingots are crushed by size.

4Packing

After thorough inspection, the pack the product.