Fine AluminaDCP

Description:

DCP-5 and DCP-4 are alpha aluminas with controlled particle size distribution after milling, separating coarse calcined alumina.

DCP-3, DCP-2 and DCP-05 are produced by grinding calcined alumina to the primary crystal size.

These are narrowly distributed alumina powders, which enable optimal filling.

These items improve the mechanical strength, chemical resistance and thermal stability of refractory, tile and ceramics.

Chemical & Physical Properties:

| Item | Spec. /Typical |

Chemical Property (wt. %) |

Bulk Density (g/㎤) |

Green Density (g/㎤) |

Fired Density (g/㎤) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | Fe2O3 | SiO2 | Na2O | LBD | PBD | 1350℃ | 1500℃ | 1650℃ | |||

| DCP-5 | Spec. | 99.5 min | 0.05 max | 0.05 max | 0.35 max | - | - | - | - | - | - |

| Typical | 99.7 | 0.02 | 0.01 | 0.27 | 0.81 | 1.24 | 2.20 | 2.20 | 2.30 | 2.71 | |

| DCP-4 | Spec. | 99.5 min | 0.05 max | 0.05 max | 0.35 max | - | - | - | - | - | - |

| Typical | 99.7 | 0.02 | 0.02 | 0.26 | 0.91 | 1.32 | 2.32 | 2.33 | 2.55 | 2.93 | |

| DCP-3 | Spec. | 99.5 min | 0.05 max | 0.05 max | 0.35 max | - | - | - | - | - | - |

| Typical | 99.7 | 0.02 | 0.02 | 0.27 | 0.94 | 1.48 | 2.37 | 2.45 | 2.69 | 3.20 | |

| DCP-2 | Spec. | 99.5 min | 0.05 max | 0.05 max | 0.35 max | - | - | - | - | - | - |

| Typical | 99.7 | 0.01 | 0.02 | 0.26 | 0.93 | 1.12 | 2.43 | 2.54 | 2.80 | 3.34 | |

| DCP-05 | Spec. | 99.5 min | 0.05 max | 0.05 max | 0.35 max | - | - | - | - | - | - |

| Typical | 99.7 | 0.01 | 0.02 | 0.27 | 0.91 | 1.10 | 2.17 | 2.65 | 3.35 | 3.77 | |

Testing method: Green Density after dry uniaxial pressing at 300㎏/㎠, 35mm∮, LBD: Loosed Bulk Density, PBD : Packed (Tapped) Bulk Density.

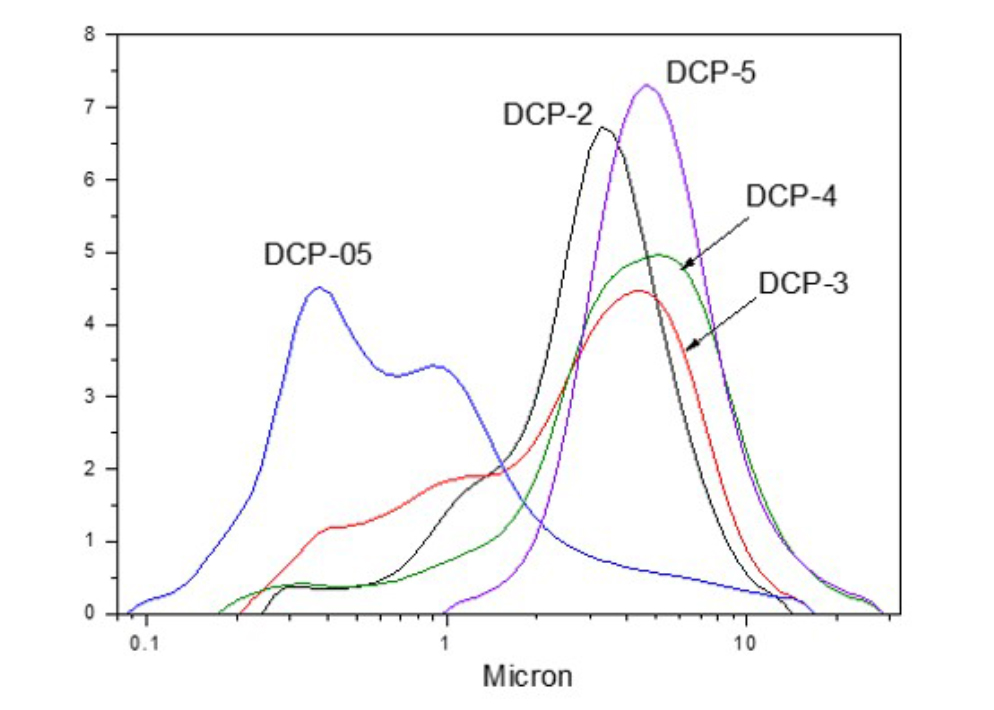

Particle Size Distribution:

| Item | Particle Size (㎛) | α-Ratio (%) |

B.E.T | |||

|---|---|---|---|---|---|---|

| d90 | d50 | Mean Size | (㎡/g) | |||

| Typical | Spec. | Typical | Typical | |||

| DCP-5 | 9.2 | 4.0-6.0 | 4.64 | 5.01 | 98 | 1.22 |

| DCP-4 | 7.8 | 3.5-5.0 | 3.92 | 4.25 | 98 | 1.38 |

| DCP-3 | 6.1 | 3.0-4.0 | 3.25 | 3.70 | 98 | 1.56 |

| DCP-2 | 4.5 | 2.0-4.0 | 2.64 | 2.50 | 97 | 2.19 |

| DCP-05 | 1.8 | 0.5-1.0 | 0.72 | 0.95 | 97 | 5.86 |

Testing method : Particle Size is Laser Diffraction Method(Microtrac), B.E.T(Specific Surface Area) is N2 Gas Adsorption Method(B.E.T Method).