Sintered SpinelSS

Description:

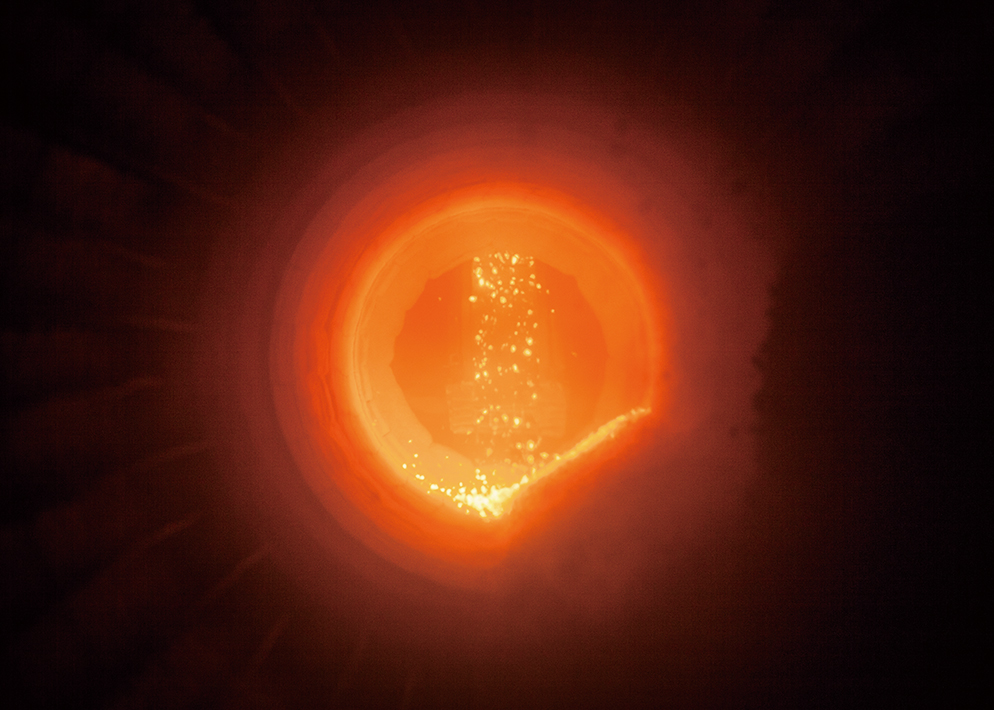

SSH is a high quality refractory material produced by compounding alumina and magnesium hydroxide which is sintered in Rotary Kiln of a temperature at about 1,850℃. SSH is formulated as MgAl2O4 and shows excellent anti-slag resistance, thermal shock resistance. These features make SSH a high class refractory material in steel making industry.

Applications:

- Iron-steel ladle Slag line Refractories

- Cement kiln sintering zone Refractories

- Ceiling Refractories of open hearth furnace

Chemical & Physical Properties:

|

Item

Grade

Property |

SS70H | SS90H | SS95H | ||||

|---|---|---|---|---|---|---|---|

| Spec. | Typical | Spec. | Typical | Spec. | Typical | ||

|

Chemical Composition (wt. %) |

MgO + Al2O3 | 98 min | 99.20 | 98 min | 99.19 | 98 min | 99.51 |

| Al2O3 | 74 min | 76.10 | 87-91 | 89.01 | 94-97 | 95.25 | |

| MgO | 21 min | 23.10 | 9-12 | 10.18 | 4.0-6.0 | 4.26 | |

| SiO2 | 0.40 max | 0.20 | 0.40 max | 0.16 | 0.40 max | 0.15 | |

| CaO | - | 0.45 | - | 0.18 | - | 0.13 | |

|

Physical Properties |

Bulk Density (g/㎤) |

3.20 min | 3.30 | 3.35 min | 3.40 | 3.55 min | 3.63 |

|

Apparent Porosity (%) |

3.0 max | 0.34 | 5.0 max | 1.85 | 5.0 min | 1.34 | |

|

Water Absorption (%) |

- | 0.17 | - | 0.53 | - | 0.37 | |

Particle Size Distribution:

| Item | Unit | Specification | Typical | |||

|---|---|---|---|---|---|---|

|

Crushed Size |

6-3 ㎜ | ㎜ | +6.70 | -3.35 | +6.70 | -3.35 |

| % | 10 max | 10 max | 0.8 | 3.2 | ||

| 3-1 ㎜ | ㎜ | +3.35 | -1.00 | +3.35 | -1.00 | |

| % | 10 max | 10 max | 0.17 | 3.93 | ||

| 1-0 ㎜ | ㎜ | +1.00 | -0.25 | +1.00 | -0.25 | |

| % | 5 max | 30 max | 2.46 | 23.65 | ||

| 14 mesh | ㎜ | +1.18 | -0.30 | +1.18 | -0.30 | |

| % | 5 max | 30 max | 0.40 | 21.30 | ||

|

Ground Size |

220 mesh | ㎜ | +0.075 | - | +0.075 | - |

| % | 5 max | - | 0.5 | - | ||

| 325 mesh | ㎜ | +0.045 | - | +0.045 | - | |

| % | 5 max | - | 0.81 | - | ||

| 90-0 ㎛ | ㎜ | +0.090 | d50 | +0.090 | d50 | |

| % | 10 max | 16-32 ㎛ | 4.12 | 24.1 ㎛ | ||

| 20-0 ㎛ | ㎜ | +0.020 | d50 | +0.020 | d50 | |

| % | 7 max | 3.5 ㎛ max | 0.1 | 2.32 ㎛ | ||